About Us

TRSA

Association for the Linen, Uniform and Facility Services Industry

Mission

Expand, protect, and promote the industry

Founded in 1912, TRSA supports the industry by building and promoting a stronger, safer and more environmentally conscious community through advocacy, education, certification, research, benchmarking and information-sharing. Members help manufacturers, service providers, healthcare facilities, retailers, restaurants, hotels and other businesses enhance their image and provide clean, safe environments for their employees and customers.

Advocacy

Engage in government relations representing the industry and conduct outreach to the industry’s customers and consumers

Certification

Uphold standards of hygiene, environmental sustainability, workplace safety

Information-Sharing and Professional Development

Provide opportunities for growth and learning through in-person, virtual, and on-demand resources

Members

Local, regional, national and global Operator Member companies (200+) supply, launder and maintain linens, uniforms and other reusable textiles and offer facility services. These members in North America account for more than 90 percent of all commercially laundered linens and uniforms in the market. Supplier Partner Members (130+ companies) provide products and services to Operators.

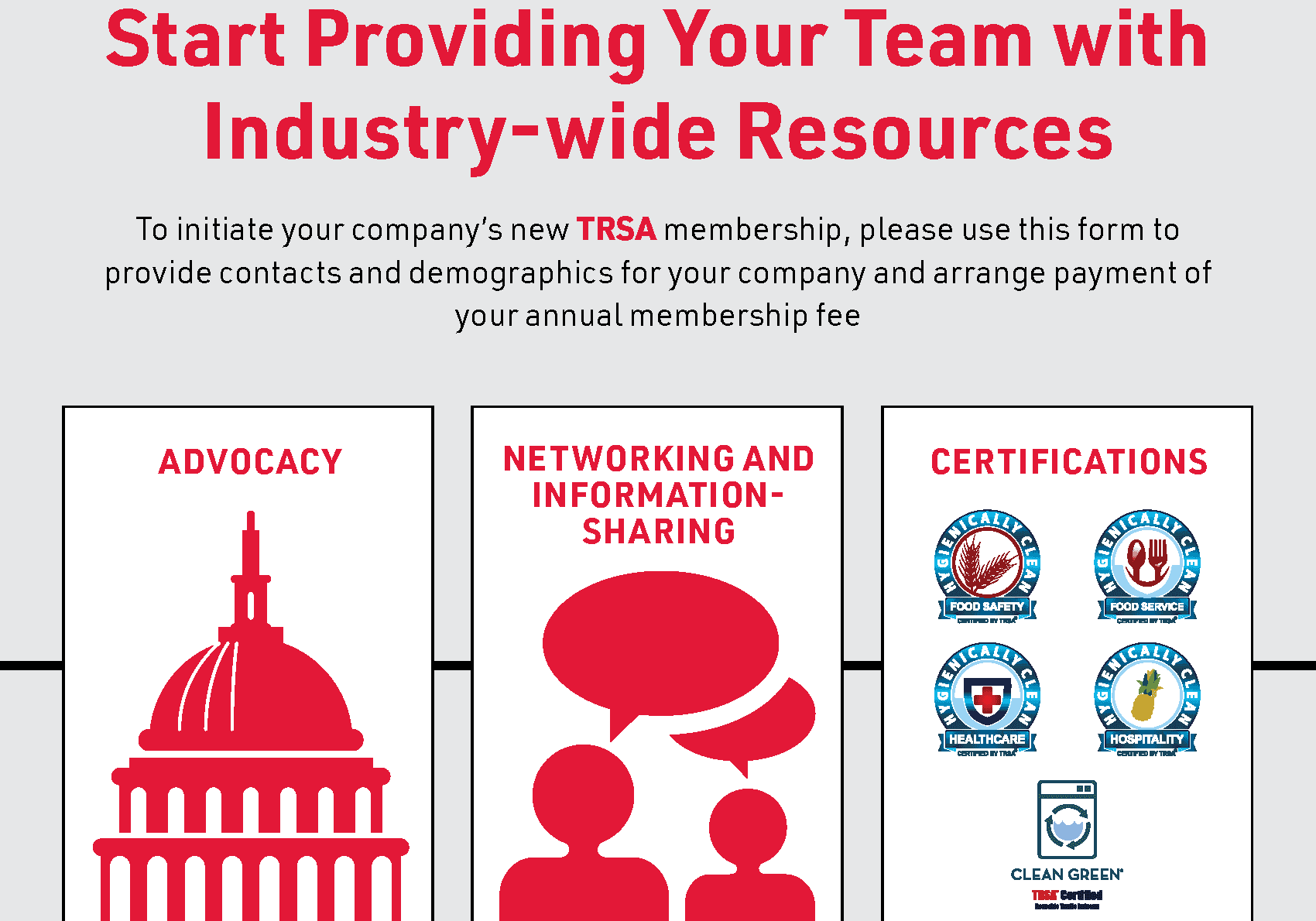

TRSA Membership

Take your place as a leading world-class company in our business by engaging with our industry’s leaders, sharing information, making your voice heard and ensuring the future of your craft.

Member Benefits

Our membership is diverse–comprised of independent operations and large national and international companies–offering you the opportunity to gain new knowledge and build your network for the future.

Applications

Take your place as a leading, world-class company in our business by engaging with our industry’s leaders, sharing information, making your voice heard and ensuring the future of your craft.

Member Resources

Gain insight into the many industry-specific compliance and safety resources and research, Career Center, Industry Directory and Buyers Guide.

Meet Our Leadership

Representatives from TRSA member companies and industry leaders serving the industrial/uniform, F&B, healthcare, and hotel/lodging markets.

Committees & Networks

Your participation in TRSA committees and task forces will help expand your professional network and enhance skills such as management, leadership, team-building and decision-making.

Awards

TRSA awards recognize individuals and teams from operator and supplier partner member companies for exemplary work efforts on behalf of their individual businesses and the industry.

Meet Our Team

A cohesive team that supports and promotes our industry by sharing information through advocacy, education, events, certification, research and benchmarking.

Get Involved

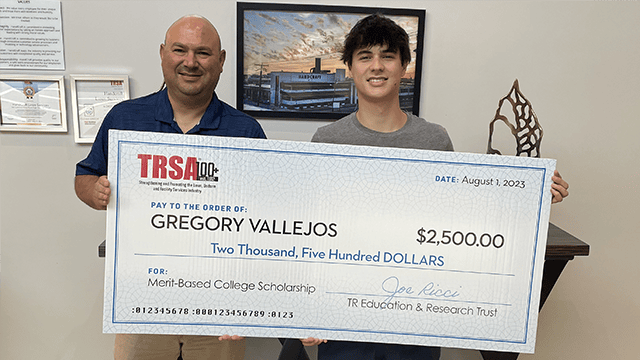

Scholarships

TRSA’s Textile Rental Education and Research Trust (TRERT) funds scholarships to support individuals seeking a career in the linen, uniform and facility services industry.

Advertising & Sponsorships

Your link to thousands of linen, uniform and facility services industry decision-makers responsible for supplying, maintaining and laundering products for various businesses and organizations