For Gabriel Mandujano, CEO of Wash Cycle Laundry, a Philadelphia-based operator that opened a new plant last year in Boston, growth in the area’s hotel market represents a welcome recovery from the recent pandemic-driven slowdown.

In less than a year since it opened, the company’s new 25,000-square-foot (2,322-square-meter) plant located in Lynn, MA, near Logan International Airport, is processing roughly 60,000 lbs. a day with a staff of 100 people working two shifts, seven days a week. They’re supplying mainly bed and bath linens to 20 area hotels, including one with more than 1,000 rooms.

This represents a big step for Mandujano, who began his laundry career as a laundromat operator in the early 2000s. Mandujano’s business model evolved in the 2010s as a business-to-consumer (B2C) service with goods delivered via bicycle. This environmentally friendly service generated a buzz, especially among young professionals in Philadelphia. The business expanded quickly into nearby cities, including Baltimore, Washington, DC, and Boston. In time, Wash Cycle shifted focus to business-to-business (B2B) hospitality laundry services. Throughout this time, Mandujano emphasized the value of providing jobs to formerly incarcerated individuals and others needing “second chances” at successful careers. This approach – coupled with partnerships with area nonprofit and government agencies – has helped Wash Cycle retain a steady workforce at its Lynn plant. That’s good news because the laundry is seeing a surge in demand for its services.

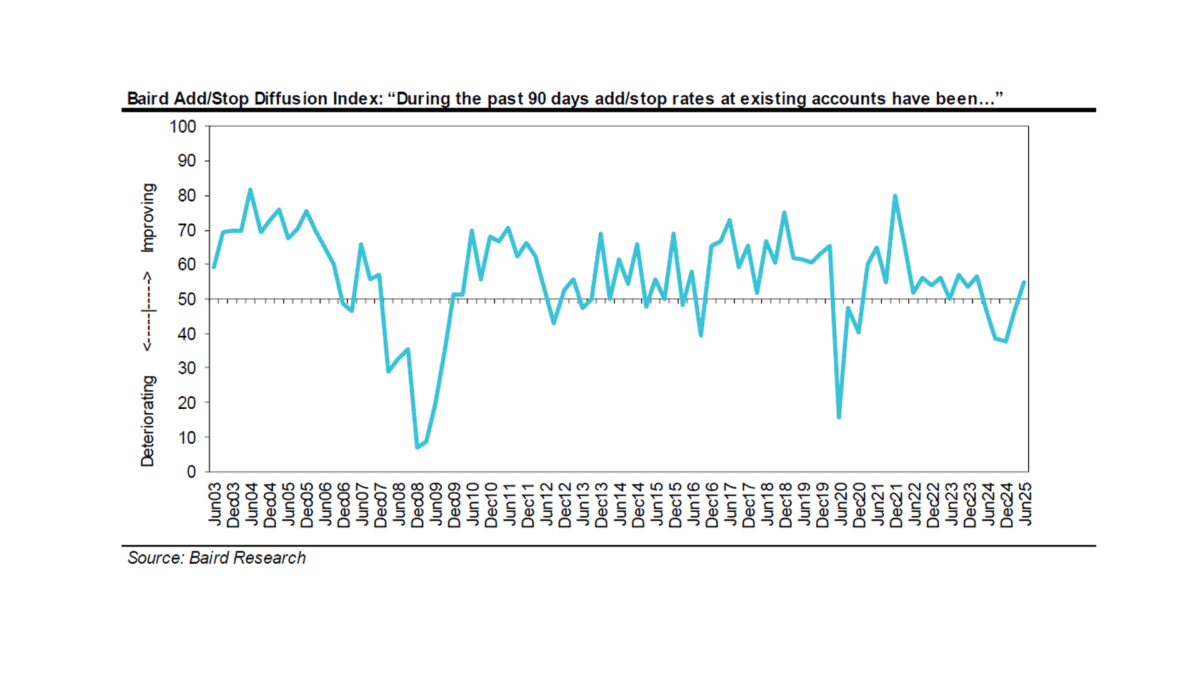

The hotel market in metro Boston has shifted in the past year, Mandujano says. In 2023, the off-season hotel trade exceeded expectations due to “revenge travel,” as people shook off pandemic restrictions to resume leisure visits to cities like Boston. “Normally winter is down. But last year it wasn’t,” he said.

While seasonal patterns are closer to normal this year, brisk growth has continued in 2024, both in terms of hotel occupancy and banquet business, he says. For Wash Cycle, that’s a sign that the long-hoped-for recovery of business travel could regain its pre-COVID-19 strength.

Wash Cycle is prepared to handle this surge in hospitality commerce with a plant that’s equipped with new wash aisle machinery supplied mainly by Sea-lion, and Lapauw, which are based in China and Belgium, respectively.

The plant – located in a refurbished dairy facility – represents Sea-lion’s first major installation in the U.S., although the company is a leading laundry machinery supplier in Asia. Ed Kirejczyk, president of Sea-lion America Co. accompanied Mandujano and a Textile Services Weekly reporter on a recent tour of the new Wash Cycle plant.

Kirejczyk, a laundry industry supplier veteran who co-founded the U.S. branch of Sea-lion in 2019, says he’s especially proud of the new 13-module, 135 lb. (60 kg.) “Laundry Dragon” tunnel washer that was installed in the Lynn plant last year. The tunnel’s design features a graphic image of a dragon on the side of the ramp that moves textiles to the mouth of the tunnel. Mandujano and General Manager John Lowrey said they’re pleased with the tunnel’s performance. Sea-lion technicians did extensive on-site work during the installation. Since then, they’ve offered guidance as needed via “WeChat” a popular Chinese social media messaging application that allows the supplier to advise maintenance staff on tunnel issues via audio/video whenever a question arises. Overall, Lowrey, a laundry-operations veteran, says he’s pleased with Sea-lion’s approach to service.

“Of course, yes there was some risk because it was not a well-known name here in the United States,” he says of Sea-lion. “But from my perspective the support that they gave us when we started up, in addition to when we have any issues, we can call them at 1 in the afternoon, our time, which is 1 a.m. there, and within a half an hour we have one of their engineers.”

Watch for more on the new Wash Cycle plant in July’s issue of Textile Services magazine. Click here for more information or to subscribe to Textile Services.

Publish Date

April 26, 2024

Categories

Sign Up For Our Newsletter

Receive the latest updates on the linen, uniform and facility services industry from TRSA delivered straight to your inbox.