As the next generation of management takes a leadership role at Rinaldi Linen Services, Waterbury, CT, the company recently invested in an innovative soil-sorting system to enhance its competitiveness, said President and CEO Jeff Rinaldi in an article slated for February’s Textile Services magazine.

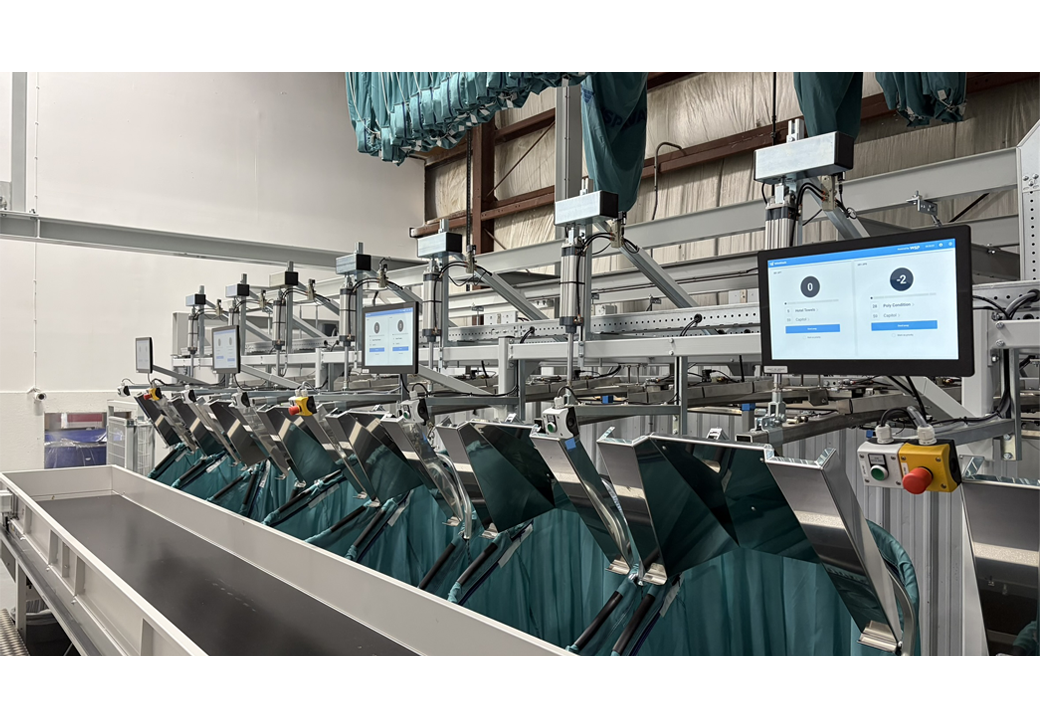

“We have one shift,” says Rinaldi, who spoke to us two weeks after the installation of new automated soil-sorting machinery/software from WSP, an equipment/software supplier. The purchase was coordinated through Lavatec Laundry Technology Inc., acting as distributor for the Netherlands-based WSP. Rinaldi says he’s pleased with the new equipment’s capabilities in the soil-sort area. “We operate from 5:30 (a.m.) until we finish in the afternoon, which is generally between 3 and 5 (p.m.). The system has saved us five FTE (full-time employee) positions.”

Rinaldi’s nephew Dennis serves as the company’s operations manager/co-owner. Jeff’s son, Ryan, also recently entered the business and serves as executive accounts manager. The company and its family management team are seeing an early return on investment (ROI) from the soil-sort upgrade. “Yes, it’s paying for itself easily,” says Jeff. “It’s increased our efficiency because of the way you have to put the amount of weight into the bag to get it into the ceiling (storage area). There’s no more guesswork involved. It takes the thinking away from the person and everything’s standardized.”

This 22,000-square-foot (2,043-square-meter) plant serves healthcare and hospitality clients in Connecticut and Massachusetts. The process of sorting soil begins when employees offload carts from trucks and roll them up to a sideways-style cart dumper. Next, employees remove plastic bags and separate linen on a breakup table. The linen moves up a conveyor/ramp to a sorting deck with 12 stations. The system has 10 sort-in-bag categories, each with a weight indicator. When the bags reach 150 lbs. (68 kg.), they are automatically moved via a WSP rail system to a ceiling storage zone. There are currently 10 “buffer lines” in this storage area, each holding 12 bags. The system can hold up to 118 bags or 17,700 lbs. (8,028 kg.). If an expansion is required, the company could add another four buffer lines with 12 bags each (48 bags/7,200 lbs. [3,365 kg.]). That plant is currently processing roughly 15 million lbs. (6.8 million kg.) annually.

After staging in the 30-foot-high ceiling area, slings of goods move to one of two newly installed tunnel washers from Pellerin Milnor Corp. Each tunnel has eight 150 lb. compartments. “That’s tracked automatically,” Rinaldi says. “This system also tells the tunnel when it’s ready and communicates with the finishing side.” This eliminates arguments between the finishing department and wash-aisle managers over what’s moving where, he says. “I know there’s some progress in that area,” Rinaldi says. The soil-sort equipment features a “WinWash” control system that fully automates the movement of goods to the tunnels.

In the past, operators have reported difficulties exchanging production information across different machines from different vendors. That’s not the case with Rinaldi Linen. “We just put in two brand-new Milnor tunnels,” Jeff says. “The (WSP) system communicates with them … almost flawlessly from what I can see.”

As staff continue to work with the soil-sorting equipment, they’re confident they can improve the system’s initial performance. “It’s amazing,” Jeff says. “We love it. And the more we work with it, the more we fine-tune it and make it work even better.”

For more on this upgrade, plus soil-sorting and finishing innovations at three other plants, watch for “Laundry Innovation – Let Tech Lighten the Load” in February’s Textile Services.

Sign Up For Our Newsletter

Receive the latest updates on the linen, uniform and facility services industry from TRSA delivered straight to your inbox.