Textile Services Weekly recently toured the new Saint Francis Health System Linen Service in Tulsa, OK – a $17 million project to replace the system’s outdated hospital laundry, while adding capacity and attracting other healthcare providers seeking linen services.

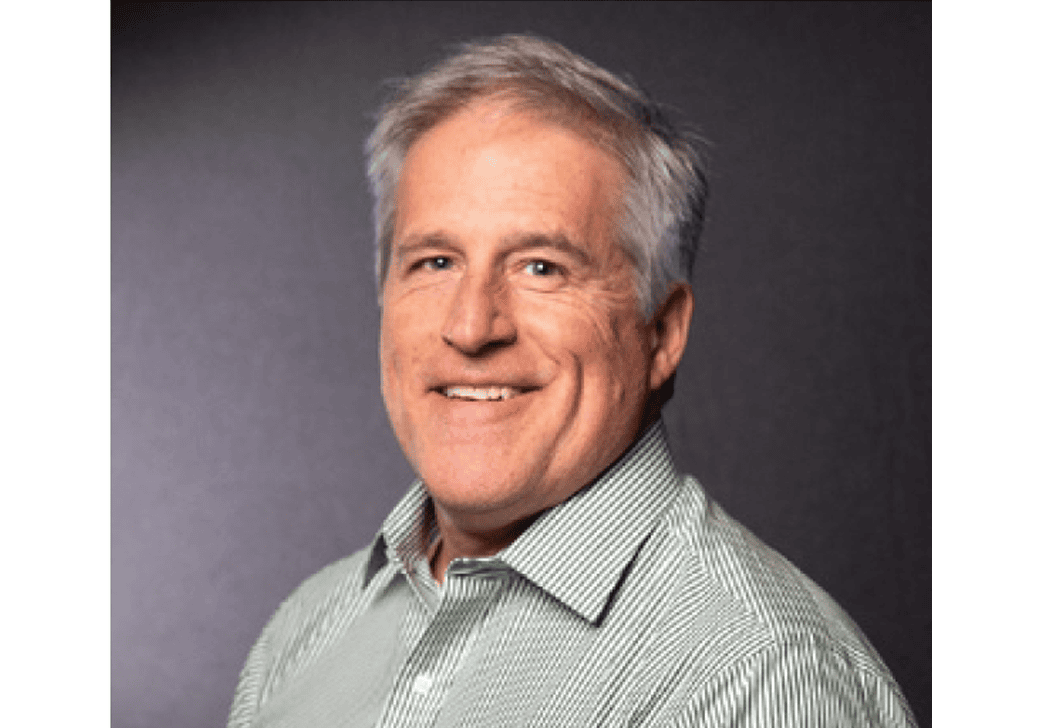

“We are talking with other healthcare facilities to see if SFHS Linen Services can assist them with their healthcare linen needs,” said System Director Mario Villarreal, who spent a decade managing the old Saint Francis laundry, before the new facility opened in June. Saint Francis is telling prospective clients, “We want to share what we’ve got with customers in Northeastern Oklahoma and deliver high-quality linens at a reasonable cost because at the end of the day, we all have a common goal of delivering excellent patient care.”

The 40,000-square-foot (3,716-square-meter) laundry is part of a larger building that houses the Saint Francis Hospital’s Durable Medical Equipment division and Supply and Distribution center. ARCO/Murray oversaw the construction, Villarreal said. He noted the improved efficiency of the new plant, which is processing roughly 320,000 lbs. (145,149 kg.) per week from two Saint Francis hospitals in Tulsa, as well as hospitals in Muscogee and Vinita, OK; plus roughly 20 clinics throughout the region.

Villarreal said he’s pleased with the ease of processing in the new plant. “We’ve become more efficient,” he said. “The equipment is lined up better than it was at the hospital. It’s easy to get the product from one end to the other. There’s a better flow. All I had was a 110 lb. (50 kg.) tunnel that ran 15 hours a day.”

The new plant has an array of new machinery, plus well-maintained equipment moved from the old site, which is roughly 6.4 miles away at 6161 S. Yale Ave., Tulsa. The tunnel noted above, which the laundry had operated for 30 years, was retired. In its place are two new tunnels from Lavatec Laundry Technology Inc. Both have 12 compartments. Compartment sizes are 110 lbs. (50 kg.) and 220 lbs. (100 kg.). Laundry chemistry is delivered via an Ecolab chemical-injection system. After cakes of clean, extracted textiles emerge from the tunnel presses, a conveyor moves them from the tunnel with 110-lb. chambers to any of four 292-lb. (132 kg.) Lavatec dryers. Goods from the tunnel with 220 lb. chambers go to any of six 292 lb. Lavatec dryers.

Other equipment operated by the plant’s 52 employees include soil sortation, overhead rails and clean-side sorting equipment from WSP Systems. A highlight of the tour was the WSP batch separator, a combination clean-side conveyor and separating system that separates tangled linen into single items. Combined with their linen supply conveyors, the linen is automatically transported and presented piece by piece at the workstation for feeding into the ironers and folders. This reduces physical strain, ensures consistent workflow, and improves overall efficiency.

This system is designed to improve workflow while reducing ergonomic strain on employees, according to the WSP website. The separator features a built-in conveyor system that facilitates the smooth movement and separation of textiles during finishing. Operators can also program the batch separator for specific types of linen, thereby enhancing flexibility and efficiency.

The plant also has a two-roll and a three-roll ironer from Vega. The rolls in both ironers are 48 inches (122 cm.).

Now that the new laundry is fully operational, Villarreal and his team hope to find new healthcare providers, thereby improving productivity and reducing their laundry-processing costs.

Villarreal said he’s impressed with the performance of the new plant and equipment. “Oh, definitely. It’s like taking your old Rambler and then buying a new Cadillac,” he said. “It’s so much more efficient.”

Watch for follow-up coverage of the Saint Francis laundry in an upcoming issue of Textile Services magazine.

Pictured Above: (l/r) Mario Villarreal, director of laundry and linen services; Michael Cowie, manager laundry and linen services; Samantha Hinson, laundry supervisor; and Laundry Supervisors Mario Alejandro and Justin Pascual stand in front of a new Lavatec tunnel washer.

Sign Up For Our Newsletter

Receive the latest updates on the linen, uniform and facility services industry from TRSA delivered straight to your inbox.