When Spotless Uniform & Linen experienced a fire that destroyed their plant in Prince George, BC, Canada, staff, vendors, other laundries, subcontractors and – most importantly – customers, pulled together to save this fifth-generation industrial business located eight-plus hours north of Vancouver.

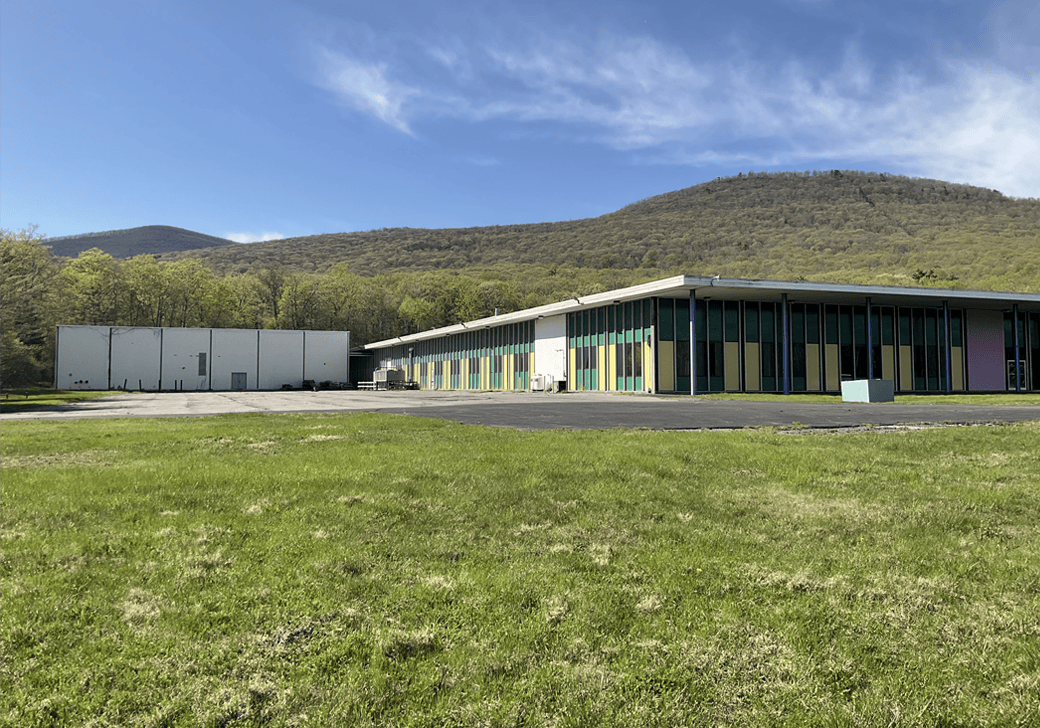

“I’m very grateful to have the team in front of me that I do have,” said General Manager Tammy Holmgren, speaking of Spotless’s ongoing effort to recover from an Aug. 5 blaze that gutted their 24,000-square-foot (2,229-square-meter) plant. Holmgren said fire officials haven’t yet announced the cause of the blaze that began in a clean-textile storage area. The laundry, located in an older brick building, wasn’t equipped with a sprinkler system, but an alarm system alerted firefighters who mobilized an emergency response. Damage to the structure and foundation is estimated at $1.9 million.

Since then, the company, founded in 1947, has shifted production to one of their other plants roughly 360 miles northwest in Terrace, BC, a hub for the Canadian liquefied natural gas (LNG) industry. A small number of subcontractors have helped fill in gaps in production. Meanwhile, the company’s 118 employees are either working in Terrace, or at a building in Prince George that was leased temporarily to keep pace with customer demand. Holmgren credits the combined efforts of staff and other players with helping the business overcome the fire, which caused no injuries. “We wouldn’t be in this position were it not for the dedicated employees we have, the vendors ensuring that our systems were back up and running and ensuring the inventory that we needed was replaced in an expedited manner. And customers were so understanding … rooting for us every step of the way to see us succeed and continue operations.”

Supplier partners, including Workwear Outfitters and IFR, did their part by rushing new supplies of uniforms to the company to replace those lost in the fire. Spotless has a protocol that ensures trucks are fully loaded at the end of each shift for the next day’s deliveries. None of the trucks, located in an adjacent lot, were damaged by the fire. The next day, they completed all their deliveries.

Unfortunately, a great deal of the plant’s mat inventory was lost in the fire. Holmgren praised M+A Matting for altering its production schedule to rush replacement mats to Spotless to meet demand that’s now beginning to surge with the arrival of winter weather. “M+A Matting has been another really huge support for us,” Holmgren said. “Our mat volume is huge, being in a northern climate, moving into our winter mat season.” M+A is prepared for these situations, she added. “They have a fire protocol where they were able to stop production and switched over to get us what we needed right away. It was really incredible.”

A third vendor of note is Alliant/TEXO. They transferred all of Spotless’s data, including customer information for the Prince George facility’s 23 routes servicing British Columbia and neighboring Alberta, to a fast, secure and user-friendly “cloud-based” server application in only eight days. Previously, Spotless had an in-house server with data backed up to an off-site location for security. Post-fire, they were using a temporary cloud server on an interim basis from a local information technology (IT) provider. “There were some speed issues with that,” Holmgren said. “It was time-consuming and slow. That’s not an issue anymore, moving over to the Alliant cloud.” Spotless is also eager to use the other Alliant programs associated with the cloud-based software, including a Business Intelligence (BI) module that will help them analyze market trends. “I think the ability to move forward with some of Alliant’s new releases that are coming out through their platform is going to be really exciting,” she said. Securing data is a key consideration for any laundry operator looking to keep its business going in the wake of a fire or other disaster. “Making sure of the integrity of your data is really critical,” she said. “Your backups need to be done off-site or stored off-site and done daily at a minimum.” Similarly, a portion of Spotless’s textile stock was stored at an off-site location, so it wasn’t affected by the fire, Holmgren said.

Another factor in Spotless’s comeback was support from other launderers, including Ecotex Healthcare Linen Service. Ecotex President Bryan Bartsch called immediately after the incident, offering to assist. Other Canadian independents such as EcoSan and Spotless Drycleaners helped as well, plus the consulting firm, Performance Matters. Various industry networking contacts have also provided suggestions and advice, she said. Important resources include contacts made at TRSA’s Canadian summits and its U.S. conferences, as well as the yearly AlliantCon exhibition and the Clean Show. “The networking is incredible because as much as we’re all spread out, it’s really a small world when it comes to this industry,” said Holmgren, who’s worked three years in the linen, uniform and facility services industry. Previously, she served in management positions with mining, construction, and biomass-power companies. “Having the partners and support … it’s impressive to me how everybody really comes together in this industry to help each other out.”

Spotless’s business and its customers’ service is secure, and they’ve recently expanded into a new service area during this challenging time, Holmgren said. That means she and the management team, including owners Shaun and Kari-Lynn Heighington, can begin planning for the future with a rebuilt laundry on the site of the plant destroyed by the fire. Holmgren anticipates it will take 18-20 months for a “complete rebuild” of the facility. Construction is expected to begin early next year. “Due to our geographical location – we’re very far north in the province – we will not be in a position where we will be able to break ground before spring,” Holmgren said. “We’re right at the beginning of where we’re expecting snow for the rest of the next five months.”

Publish Date

October 30, 2025

Categories

Sign Up For Our Newsletter

Receive the latest updates on the linen, uniform and facility services industry from TRSA delivered straight to your inbox.