In 2023, U.S. News & World Report ranked The Broadmoor as the nation’s 10th best resort property. Earlier this year, Forbes Travel Guide renewed its five-star rating for the 64th consecutive year, the longest active streak for any hotel worldwide. When it was time to upgrade their laundry equipment two years ago, management turned to LAVATEC.

“Expectations for a five-star, five-diamond resort are like no other,” said John Fish, The Broadmoor’s chief facilities maintenance mechanic who has worked at the property’s OPL for 41 years. “Our linens must be of impeccable quality and cleanliness, and no stained or torn linen is acceptable. Guest demands are met to give a superior stay experience.

“Demands on our laundry department can at times be a challenge. We have employees who are flexible, and equipment that is part of a resilient system to accomplish the needs of the hotel and our guests. Adding the new LAVATEC tunnel washer and other equipment has enhanced the quality and production of our laundry.”

Owned by Denver-based Anschutz Corp., The Broadmoor has grown to 5,000 acres with 784 on-site rooms. To accommodate guests, there are 20 retail boutiques, diverse restaurants, cafes and lounges, two legendary golf courses, a world renowned five-star spa, and over 315,000 square feet of indoor and outdoor meeting space.

The responsibility for maintaining the mountain of laundry produced daily at the complex belongs to Fish and laundry manager Anthony Cruz, who joined The Broadmoor in 2019 as the assistant director of housekeeping. They manage a staff of 35 employees who rotate shifts seven days a week, and another 21 people who work on the dry-cleaning side six days a week.

The laundry facility itself requires 60,000 square feet of space, plus a separate 6,000 square feet for dry cleaning. Last year, the department processed 4.5 million pounds of laundry. They are projected to finish 2024 with an increase to 4.7 million pounds.

“The mix of laundry items we produce is vast,” said Fish, noting the 784 rooms account for just 60% of the total production. “We run all hospitality linen sheets with a 60/40 blend, including duvets, shams, terry towels, rugs and microfiber robes. We also process linen for three of our mountain properties.”

Those properties account for another 40 rooms, starting with the 22 cabins at Cloud Camp. The popular all-inclusive offers sensational views at 9,000 feet above sea level. The Broadmoor Emerald Valley Ranch contains 13 cabins, and there are another five cabins at Fly Fishing Camp, which is located 75 miles west of the main resort.

“We process all of these linens daily during the months of May to October each year,” Cruz said. “The cabins are very popular and are usually sold out during the summer, so we use our vans to deliver twice a day.”

Fish says the other 40% of the laundry work is split between several sources.

“Food and beverage is a mix of Visa and cotton linens, and the napery is cotton we service for 19 different restaurants and convention services around the property,” Fish said. “We handle all sizes, ranging from napkins to 22-132 inch round tablecloths. This work equals about 30% of our production.”

Fish said the remaining balance is generated by the golf club and spa, and the outdoor pool. These venues are extremely busy in the summertime and increase the poundage rate by needing to clean 5,000 to 7,000 towels per day. The laundry department also includes a dedicated dry-cleaning section which handles guest needs and any outside visitor guest requests.

“We use two route trucks and have a public counter area for any of the outside customers,” Fish said. “We also dry clean the uniforms of our 2,000 employees, using two dry-cleaning machines and four, 60-pound washers to handle the 5,000 to 6,000 pounds of wash per week.”

Cruz and Fish did their homework researching new equipment to replace their aging machines in the laundry department. The now two-year-old LT60 tunnel washing system, with 10 compartments and 132-pound capacity per chamber, is connected to four new TT-746 natural gas dryers with 292-pound capacity via a LAVATEC conveyor system. A fifth dryer operates independently with three separate conventional washers.

When decision time arrived at The Clean Show in Atlanta, they said the math pointed them in LAVATEC’s direction to replace a trio of 21-year-old washers and four larger drying units. Fish explained how the new equipment is having a positive impact on the laundry department’s sustainability efforts.

“Our production day this past summer changed significantly,” Fish said. “Instead of running 10-12 hours a day for seven days, we reduced it to 8-10 hours. Our water usage has decreased about 50%, with hot water being generated faster in 40% less time. Our gas usage is also down about 30%. Overall, our labor hours have been lowered by about 20% in the summer, and linen life and quality is up.”

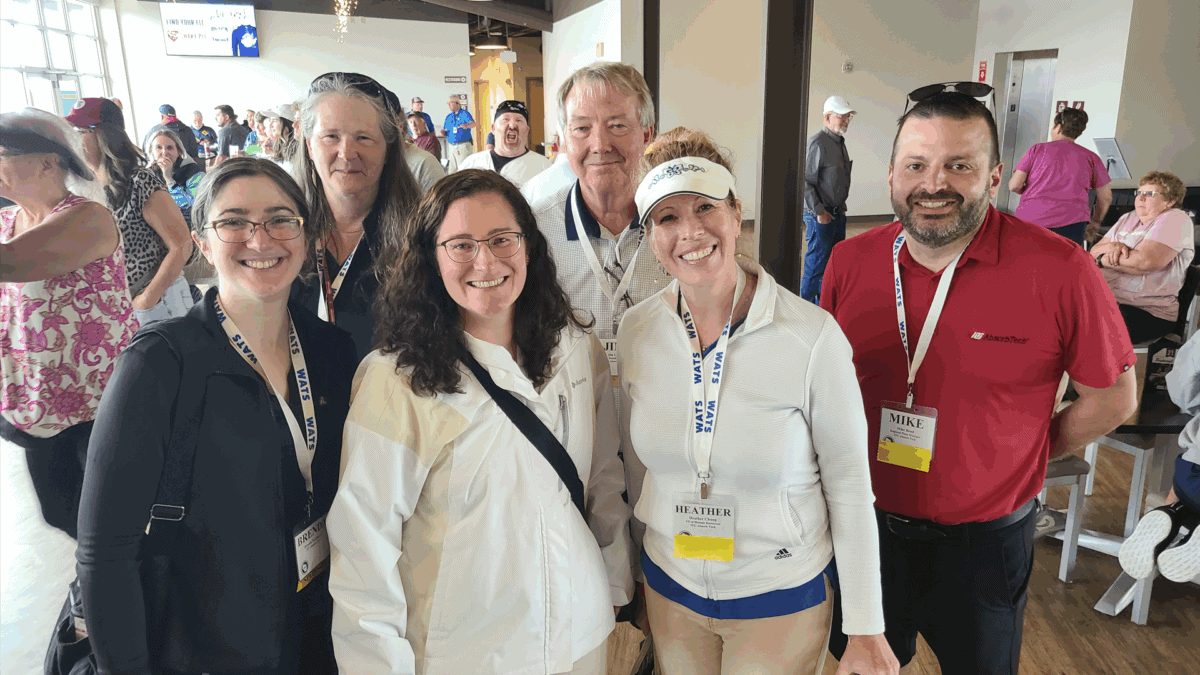

After entertaining guests for the TRSA Annual Conference two months ago, and with a new year on the horizon, Fish is looking ahead to more new challenges.

“The Broadmoor hosts thousands of conferences like TRSA,” Fish said. “Some groups have hosted their events here for decades, and there will also be new ones joining our tradition.”

To read the full article, click here.

Sign Up For Our Newsletter

Receive the latest updates on the linen, uniform and facility services industry from TRSA delivered straight to your inbox.