Medico Healthcare Linen Service, a metro Los Angeles independent, is leveraging its services to cater to the growing outpatient market in Southern California, as you’ll see in Textile Services’ upcoming March profile of the company’s Long Beach plant.

In the article dubbed, “Outpatient Care: Medico Long Beach Catches the Wave,” Medico Operations VP Greg Shames affirms Southern California’s recent shift to outpatient medical services. “Our customers are experiencing a rise in their outpatient-care services,” says Shames, whose company also operates a healthcare plant in South Gate, a municipality located about seven miles southeast of downtown Los Angeles. Shames says that another aspect of this recent shift to outpatient care is that healthcare consolidation has led to fewer independent clinics and more hospital-affiliated outpatient centers.

The expansion of outpatient care in So-Cal is well documented. A 2021 report by the California Health Care Foundation found that from 2014-’18, outpatient healthcare sites grew by 27%, while the number of patients served by these institutions expanded by 33%. The area’s growth in healthcare has put pressure on Medico’s 45,000-square-foot (4,180-square-meter) Long Beach plant, which it acquired in 2005 from Angelica. In response, the parent company, American Textile Maintenance (ATM), soon will open a third plant in fast-growing San Bernardino, about 70 miles east of Los Angeles. That plant is expected to open in the second quarter of this year.

As for the Long Beach facility, it’s currently processing roughly 450,000 lbs. (204,116 kg.) of healthcare textiles weekly with a staff of 145 production employees working two shifts. While the labor shortages common during the COVID-19 pandemic have abated somewhat, recruitment/retention continues to require a significant commitment, says Shames. Keeping the Medico plant staffed takes a proactive approach, including referral incentives and dedicated hiring efforts. “We experience a 10%-20% churn among entry-level staff, which keeps us focused on continuous recruitment,” he says. “Fortunately, our HR team, with skilled recruiters, plays a vital role in maintaining workforce stability.”

Another challenge is keeping pace with the Golden State’s rigorous environmental rules, including a recently loosened mandate to convert commercial fleets to 50% zero-emission vehicles (ZEVs) by 2035. On Jan. 13, The California Air Resources Board (CARB) dropped its waiver request to the U.S. Environmental Protection Agency (EPA) to implement the Advanced Clean Fleets Rule (ACF). That regulation would have mandated the purchases of ZEVs with a goal of having fleet operators in the state convert half of their box trucks to ZEVs by 2035. Industry observers in California commented that the hostility to the regulation by the new administration of President Donald Trump spurred CARB to drop the rule. Others have claimed the rule is unworkable due to limited infrastructure, especially for electric vehicles. In any event, there’s currently no rule to force companies to buy ZEVs. That’s unlikely to change until Trump’s term expires on Jan. 20, 2029.

Meanwhile, ATM is moving forward with its sustainability goals, including the planned installation of seven charging stations for its electric vehicles. American Textile Maintenance has 10 EVs on order, with the first expected to arrive shortly. Saving water is another high priority for Medico’s commitment to resource conservation. This includes the Medico Long Beach plant’s rehabilitation of an on-site well that now supplies water for its wash processing. Medico also recently received a certificate of recognition from the Long Beach Water Department for excellence in wastewater management.

Beyond the mechanical room, the plant features a number of efficiency-driven innovations, including radio frequency identification (RFID) tags from Positek RFID to track its movement of garments through the plant, plus productivity tracking through Spindle software.

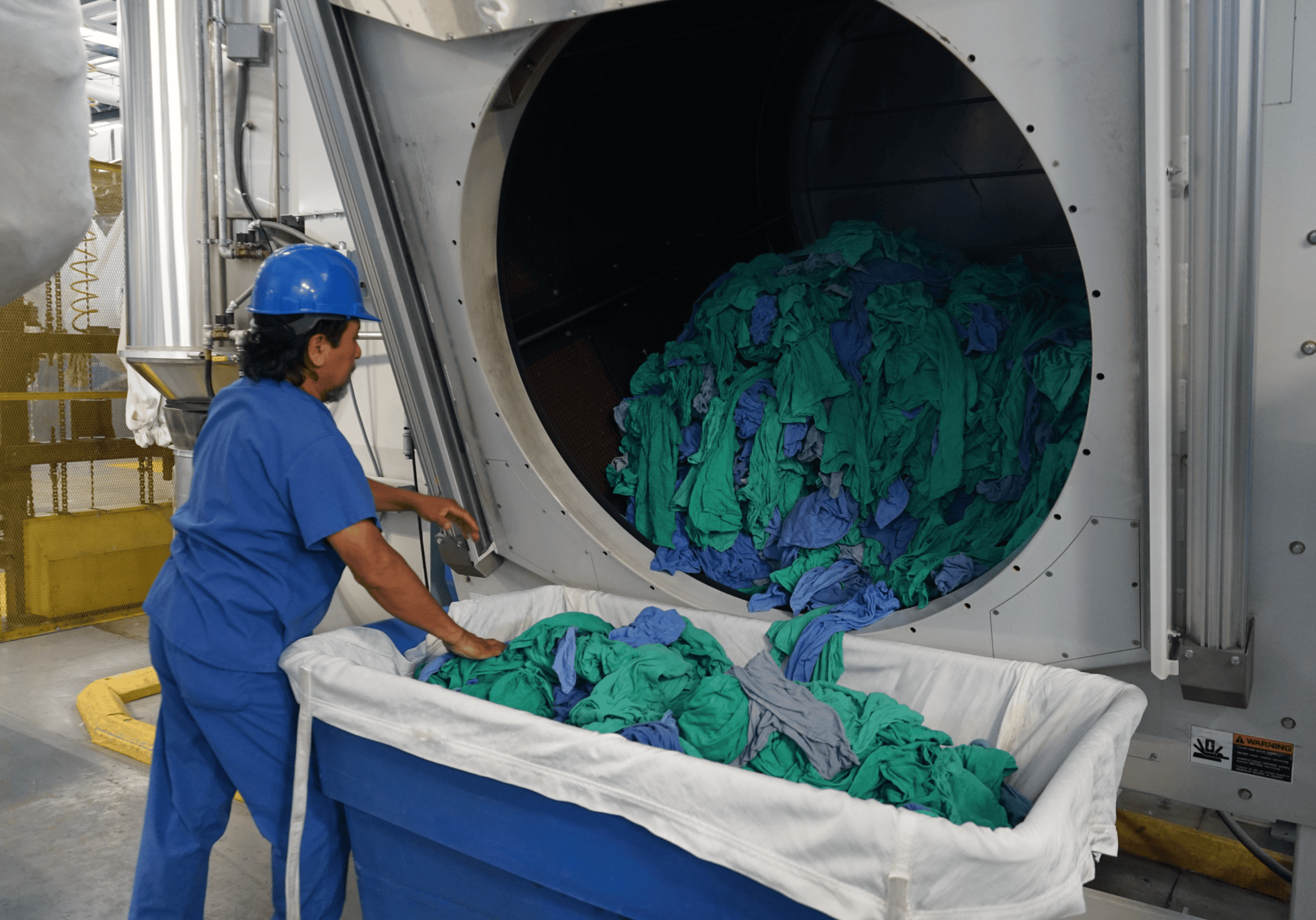

The wash aisle includes an ETECH overhead rail system that feeds slingloads of textiles into a Senking/JENSEN tunnel washer with 14, 200 lb. (90 kg.) chambers. The plant also has washer/extractors in varying sizes from Brim Laundry Machinery Co. Inc., Ellis Corp., JENSEN and Pellerin Milnor Corp. Ecolab Textile Care Division provides wash chemistry for the plant. The finishing side of the plant includes a Metricon garment-sortation system from JENSEN, plus three ironer lines from JENSEN and seven small-piece folders from JENSEN and Foltex. Shames says he’s eager to get the San Bernardino plant up and running as soon as possible because the Long Beach plant is nearly at full capacity. “This plant is extremely busy, and we’re excited to bring the new facility online,” Shames said. “We’re seeing hospitals acquiring outpatient sites and expanding their reach. Our business is shifting to accommodate that trend.”

Click here to preview a PDF of the March article on Medico Long Beach.

Sign Up For Our Newsletter

Receive the latest updates on the linen, uniform and facility services industry from TRSA delivered straight to your inbox.